Case study

Bone-like lattice structures

Introduction

Currently there are two main paradigms for generating lightweight structures for Additive Manufacturing (3D Printing):

Topology optimization

Lattice structures

Generally speaking, there are four types of lattice structures:

In an ideal situation, designing lattice structures just like nature does is more optimal.

This is because lattice structures are the strongest if aligned in the direction of stress.

Solution

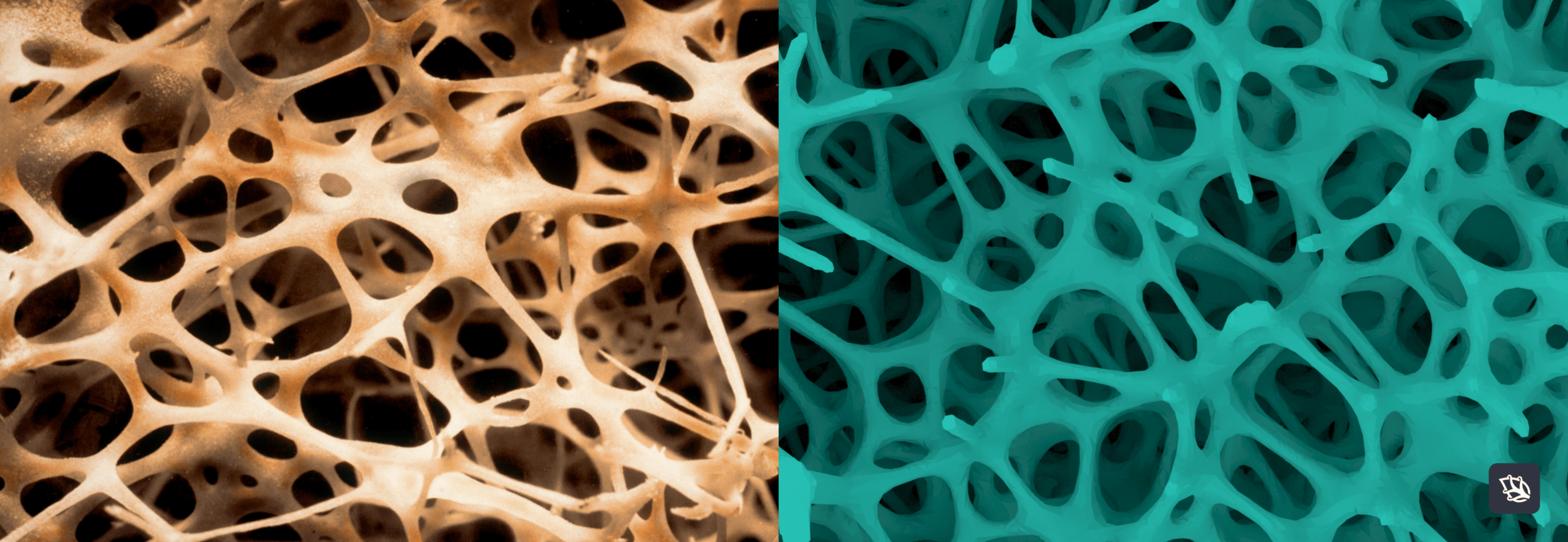

That is why we at Genic have develop an algorithm that mimics trabecular bone structures

Inspiration

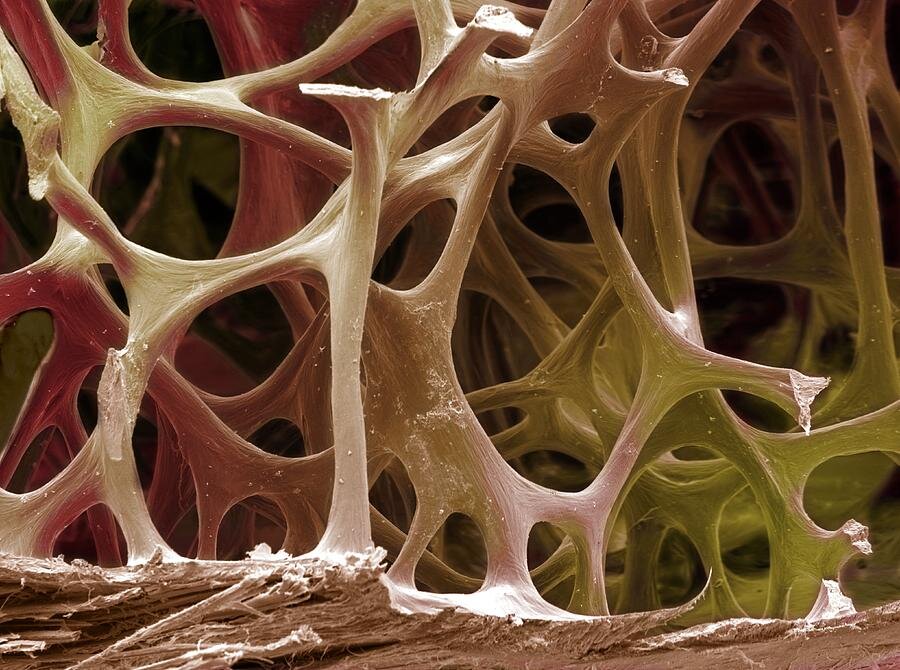

Trabecular / cancellous bone

These are porous bone structures, that according to Wolff’s law, characterize in continuous remodeling of their topology in response to applied stresses and demands.

We stepped away from the traditional voxel-based approach of creating lattices, to create trabecular structures that are adjusted to withstand simulated tensile and compression stresses.

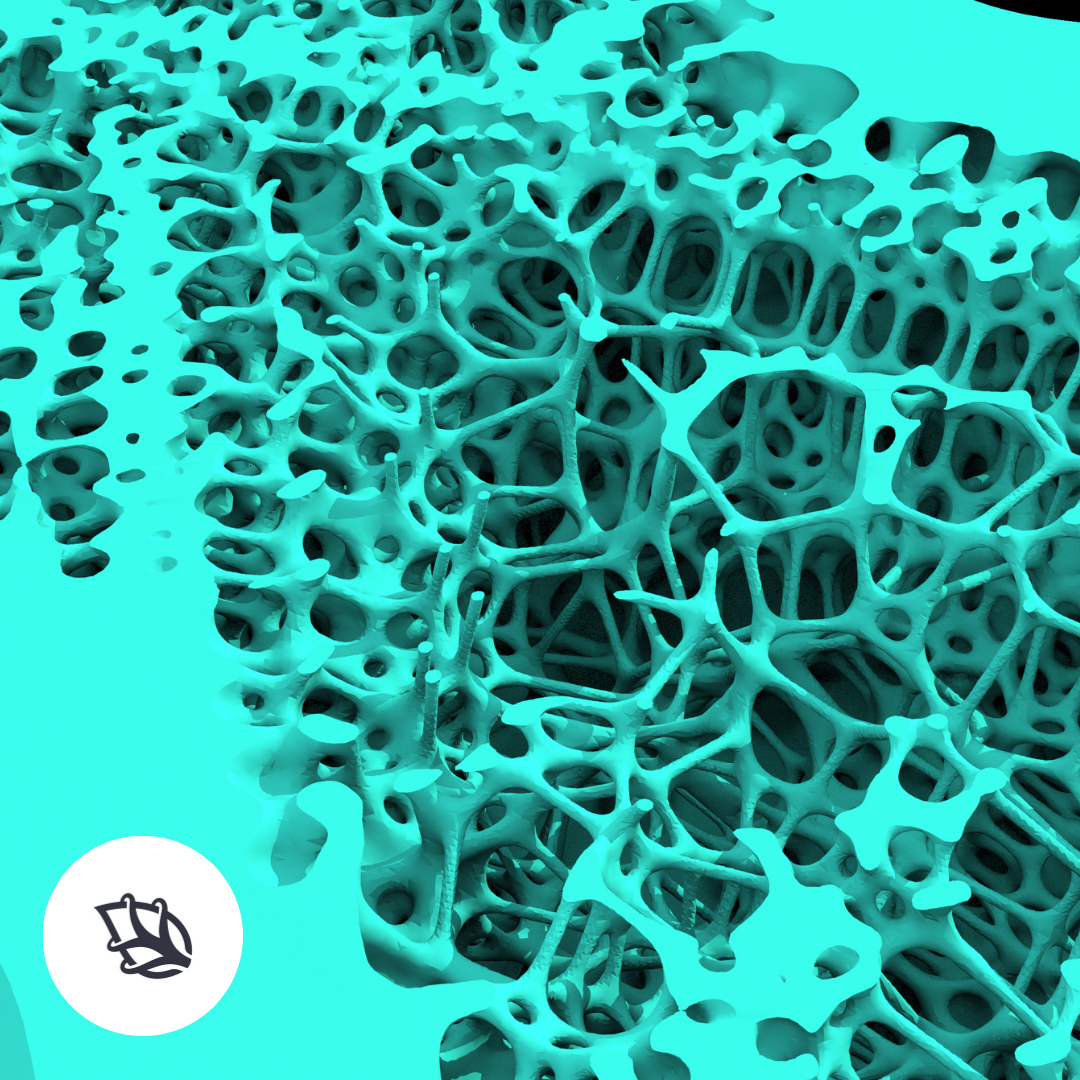

Our optimization process of the lattice structures starts with defining:

design space,

material properties,

objective function.

Using Evolutionary Solvers, our algorithm works in closed loop, gradually refining the topology based on built-in simulation.

The creation process is finished wherever the pre-set objectives are met.

Vision

We believe that in the near future the role of product designers will shift,

from mastering the solution, to mastering the problem.

Nowadays, the function of CAD & CAE tools is almost entirely limited to recording the decisions made by human operators.

Designers of tomorrow will be setting up their computers and servers to refine their designs for them.

We say that ‘Complexity is for free’ with 3D Printing. But on the other hand, the manual design process for highly sophisticated parts could take weeks or months.

Our approach is to package the design rules into Generative Algorithms, that allows us to repetitively refine 3D printed component design in almost no time.